Changyou Glass - glass packaging manufacturer providing one-stop sourcing services

·Rapid Design-to-Sample Cycles – Digital 3D models, on-site mold shop, and pilot lines compress lead times to as little as 4-5 weeks.

·Uncompromising Quality in Premium Glass Bottles – ISO 9001 production, CCP monitoring, and multi-layer inspections guarantee each bottle matches the approved sample.

·Full IP Protection for Exclusive Bottle Designs – Client-funded molds are strictly exclusive; NDAs and mold agreements safeguard your proprietary designs.

·Flexible MOQ & Cost Control – Low-MOQ custom bottles start at a few thousand units; full custom molds typically begin at 10 000 pcs, with bundling and phased shipments available.

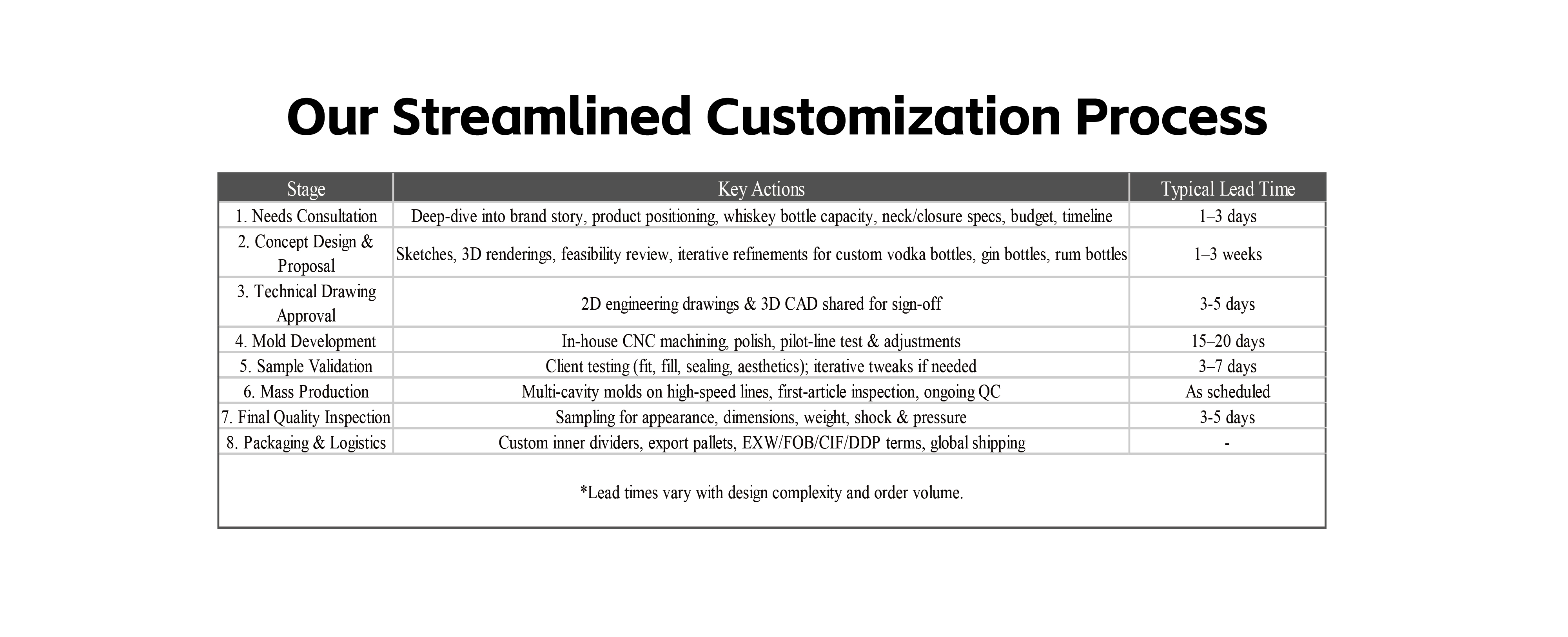

OEM/ODM Service

We are committed to streamlining the process of turning your concepts into reality through our OEM/ODM service. Our priority is to tailor products to your specific requirements, guaranteeing that you effortlessly and conveniently obtain the optimal solutions.

Whether it's printing vivid patterns that bring out the unique charm of your brand, creating embossed logos that add a tactile dimension and a sense of quality, or applying elegant hot stamping that exudes luxury and sophistication – and so on – we are dedicated to transforming your vision into a reality, elevating your packaging to an art form that stands out in the market.

Whether you have a specific concept in mind or are looking for inspiration, our design team will work closely with you to understand your vision and create a logo that not only reflects your brand's personality and values but also stands out in a crowded marketplace. By choosing our service, you are entrusting your brand's identity to a team of experts who are committed to delivering a customized logo design that is truly unique and tailored to your specific needs.

Whether you desire a sleek and modern design or a more traditional and ornate shape, we have the skills and resources to bring your ideas to life. By choosing our customized bottle shaping service, you are not only getting a unique packaging solution but also a statement piece that sets your product apart from the competition and defines distinctiveness in the marketplace.

In the glass bottle production process, we initially invite clients to contact us through our provided channels, followed by discussions to understand their specific requirements and budgets. Once a consensus is reached, we sign a formal cooperation agreement detailing product specifications and delivery details.

Delivery time

Controlling the delivery time of glass bottle is a multi-faceted process that requires careful management from multiple aspects such as supply chain planning, production planning, and progress tracking. If you have special and urgent orders, please let us know and we can coordinate internally to help you achieve your delivery goals. Normal orders usually take 25-30 working days. For some items that are very similar to our main products. The delivery time may be only 7-15 days.

Shock absorption performance

Whether it is a road transport vehicle, a railway carriage, a ship or an airplane, the means of transport should have certain shock absorption performance. For example, in a road transport van, a shock-absorbing rubber pad can be installed at the bottom of the carriage, a shock-absorbing spring can be set in the railway carriage, and the bottom of the ship's cargo hold can also be paved with shock-absorbing materials.

Fixing device

The means of transport needs to have appropriate fixing devices to ensure the stability of the wine bottle packaging. In the truck compartment, ropes, tensioners, etc. can be used to fix the goods; in the container, the wine bottle packaging is fixed in the appropriate position with brackets and tie straps; in the ship's cargo hold, the wine bottle stack is fixed with ropes or special cargo fixing racks.

Environmental control

For some glass wine bottles that are sensitive to temperature and humidity (such as bottles containing high-end wines), the means of transport needs to be able to provide a relatively stable temperature and humidity environment. In road transportation, refrigerated trucks or insulated trucks with temperature and humidity adjustment functions can be used; in railway transportation, there are special refrigerated containers; similar temperature control equipment is also available for water and air transportation.

In the glass bottle production process, we initially invite clients to contact us through our provided channels, followed by discussions to understand their specific requirements and budgets. Once a consensus is reached, we sign a formal cooperation agreement detailing product specifications and delivery details.

No. 7 Tongshi South Road, Zhifu District, Yantai City, Shandong Province, China